NAMAN CONFERENCE HALL

Nhà Hội Nghị Naman

Specifications | Khái quát

---

Location

Naman Retreat Resort, Truong Sa road, Da Nang, Vietnam

Program

conference

Design Year

2014

Status

built in 2015

Site Area

belongs to the resort

Floor Area

773 m2

Design Firm

Vo Trong Nghia Architects

- Design Major Team

Trong Nghia Vo (architect in charge), N Quang Dau (team leader - project architect)

- Others

-

Architects: Hai Vu, Thuy Duong Ngo, Q Bao Hoang & Internships - Students

Add info about Positions

-

Architect in Charge: KTS Chủ trì

-

Team Leader - Project Architect: Trưởng Nhóm - KTS Phụ Trách Dự Án

-

N Quang Dau - MODS, was the Project Architect while he was working for Vo Trong Nghia Architects.

Structural Firm (concrete part)

Viet Structure

- Engineers

Van Canh Tran

MEP Firm / Engineers

Thanh Pham (team rep)

Bamboo Contractor

Vo Trong Nghia Architects

- Construction Manager

Ba Tuong Nguyen

Client

Thanh Do Investment Dev and Constr Jsc

Photographs (ảnh hoàn thiện)

---------

---------

Overall Description

THUYẾT MINH TỔNG QUAN

-----

(the overall description from Vo Trong Nghia Architects design firm)

------

The Conference Hall is the first building of the facility of Naman Retreat Resort that the guests can see when approaching the reception zone. The hall can accommodate up to 300 people at once and can serve for different occasions such as conferences, lectures, concerts, meetings etc. It is a rectangular shaped hall with an asymmetrical pitched roof. The vault bamboo structure gives the building an iconic and impressive look. The building consists of 2 parallel spaces: the closed hall and the open corridor. The exterior corridor serves as an outdoor lobby as well, welcoming the guests.

The main bearing structure are the bamboo frames which overcome a span of 13,5 meters in the hall and 4 meters in the corridor with the roof height of 9,5m. The arch-like impression is created by the bent bamboo that are part of the main structure. Thanks to the positioning of the glass facade which is stepped backwards into the volume, 3 frames of the arch structure are in the exterior, opening the entrance as the space serves as a foyer to welcome the guests.

There are 2 types of bamboo used in this building. The straight one, bamboo named Luong was chosen for its harvestable height that can reach up to 8 meters, longer than the bending type and they were composited to be the roof battens. For the arches the “Tam Vong’ bamboo was used thanks to its flexibility features. The design follows the features of each type to combine them in a most efficient way.

The reason of using the bamboo as a main material, beside architecture, came from the requirements of the clients who wanted to have a simple big open space to provide flexibility for different functions with the reasonable construction costs and fast construction schedule. The bamboo can deliver all of these features. Its is a local and affordable material and the construction time was very fast due to prefabrication of the frames on the ground. This construction method was proven to be very efficient and it provides better control over the construction.

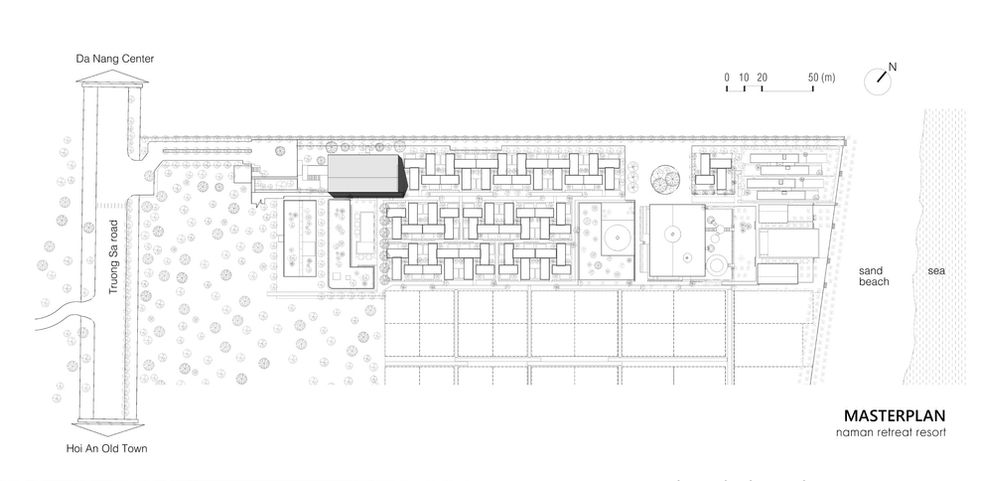

note: rendering image

- back of house: nhà điều hành và phụ trợ

- bungalow area: khu ở bungalow

- hotel: khách sạn

- road: đường, lối đi

- roof line: vị trí đường rìa mái

- sand beach: bãi biển

- sea: biển

- to Da Nang Center: hướng đi Trung tâm tp Đà Nẵng

- to Hoi An Old Town: hướng đi phố cổ Hội An

- to the gate of the resort: hướng ra cổng của resort

- to the beach: hướng ra bờ biển

Trường Sa road: đường Trường Sa

1. Main Entrance

2. Side Entrance

3. Roofed Patio

4. Foyer

5. Hall

6. Female Wc

7. Male Wc

8. Handicap Wc

9. Small storage

10. Break room

11. Storage, Technic

12. Pond

13. Grass yard

----

----

Additional Descriptions

PHẦN TRÌNH BÀY BỔ SUNG

-----

(The addition written by N Quang Dau, Project Architect for Vo Trong Nghia Architects, now founder of MODS)

The “straight bamboos” have joined to create Dai Lai Conference Center which is already introduced in the same Public Buildings category. In that project, it is mentioned in several words about the “bending bamboo”, and here is the expression a little bit more about this tree. Tam Vong - the Vietnamese name of this bamboo, is a preeminent species in Vietnam and several countries in Southeast Asia. Not only can be used Tam Vong trees as straight columns, battens and beams because their trunks are as solid as wood, people also can bend them to be curved ones due to the bendable capacity of the tree trunk; and together with the good elasticity that the trunk is able to provide, to contribute as other useful structural elements and create various architectural forms. With their such properties and ability, for this building, Tam Vong bamboos have helped the architects to enlarge the frame span up to 13,5 meters, achieved the creating an average auditorium as well as the ability of serving as a multifunction hall, of which the internal views are unobstructed. This distance is also worth-considering for concrete beam.

-----

other drawings

before and after | trước và sau

----

This presentation is accompanied by construction photos right below. They illustrate the overall structure that: The rigid frame was made of cast-in-place concrete, roles as flat elements to construct partitions, attach the glazings, doors and windows. It also supports for bamboo structure in case there are very strong winds of the seaside. However, the concrete frame does not join as the main bearing structure; in this case, the bamboo structure includes bamboo columns, girders, big bent cruck-blades and the roof structure which combined together to become a hard system that basically can afford to stand by itself. All bamboo frames had been prefabricated at another site before they were moved to the building site. The workers who work on concrete part often follow the drawings but concrete workers and bamboo workers also connected together to know well real situation of work part of each side, especially is the changing of each interval caused the parameters of bamboo frames being different from their drawings. This can be explained that, bamboo is resilient, and elements of a composition like a truss or a frame are usually extended themselves to be larger. Thus, when the concrete part was completed, bamboo workers had to adjust all bamboo frames again, to assure that they would adapt with the concrete part. After that, one by one bamboo frames were carried on and put exactly to their positions on the ground which had been determined before.